In-plane micro-supercapacitor

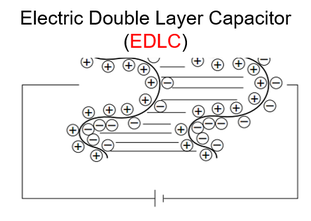

A micro-super-capacitor (MSC) is an energy storage device, also called an electric double-layer capacitor, that charges and discharges by the physical adsorption and desorption of ionic species on the electric double layer of electrodes. While a capacitor (Fig. 1a), which stores electric charge between two parallel electrodes, suffers from rapid self-discharge, MSCs store energy through the physical adsorption of ionic species, making them much less self-discharging than capacitors. device.

Conventional MSCs have a sandwich-type structure, consisting of opposing electrodes and a separator as shown in Fig. 1b, which is similar to the structure of a lithium-ion battery. On the other hand, the planar MSC consists of a interdigitated electrode and electrolyte as shown in Fig. 1c, and has been studied intensively by research institutes in other countries in recent years. In Japan, our group has reported a pioneering study. In the field of in-plane MSCs, the preparation of conductive carbon interdigitated electrodes by laser direct writing on a resin film substrate has been an effective method. However, it seems that the planar MSCs have not been studied in Japan, perhaps because laser processing and electrochemistry are quite different fields.

In the movie 1 below, a flexible film-type in-plane micro-supercapacitor (MSC) is employed as a backup energy storage device for a solar cell. At around the 20-second mark of the movie, the MSC is working even though it is hardly bending. This is because the electrodes of an in-plane MSC is composed of a conductive carbon interdigitated electrode that do not require a separator. In-plane MSCs are safe devices for wearable applications where bending is expected.

Fig.1 Comparison of various capacitor structures.

Fig.2 Charge-discharge mechanism of supercapacitor (electric double layer capacitor) based on adsorption and desorption of ions.

【Movie1】Flexible in plane MSC (micro-supercapacitor) as a solar cell backup device.

However, although in-plane MSCs are being intensively researched and developed in China, the U.S., and other countries, they are not yet at the stage of practical application. This may be due in part to the fact that applications suitable for planar MSCs, such as flexible wearable devices, devices powered by environmental energy, and wireless powered sensors, which are expected in the next generation, have not yet been widely used practically. If the storage capacity is simply to be increased, conventional MSCs are more advantageous because their capacity can be increased with their thickness (the amount of material involved in charging and discharging).

We think that the challenge is the applications development of in-plane MSCs that can take the advantage of in-plane MSCs, such as thinness, flexibility, and safety at the same time as improving the characteristics of them.

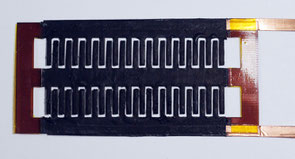

Fig.3 Prototype sample of an in-plane MSC.

Pseudo-supercapacitor

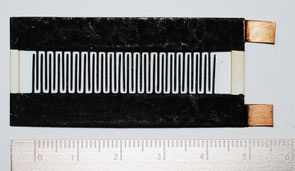

The challenges for in-plane MSCs include further improvement of capacitance and energy density, and the development of a safe solid electrolyte that can replace acid gel electrolytes. We are investigating solid electrolytes composed of polyvinylalcohol (PVA) and redox species, and developing a pseudo-supercapacitor, which has both capacitance by adsorption-desorption of ionic species and charge-discharge characteristics like a rechargeable battery by redox reaction of chemical species. Pseudo-supercapacitors can significantly improve capacitance and energy density due to the addition of secondary battery-like characteristics to the capacitive characteristics of MSCs. The carbon electrodes as shown in Fig. 4 are made by laser-cutting a resin film, paper (Fig. 5), and non-woven fabric sheets and coating them with a conductive carbon paint. Both the front and back surfaces act as carbon interdigitated electrodes, and the holes between the comb electrodes can hold solid electrolytes (JP2020-193710).

Fig.4 2 series carbon interdigitated electrodes.

Fig.5 Paper-based carbon interdigitated electrode.

These are just a few examples of the services we can provide. All of them can be produced with on-demand laser processing. Customization and sample prototyping are available. We offer laser processing to create electrodes for planar MSCs, prototype planar MSC devices, and evaluate device characteristics.