Wearable UHF-band RFID tag

In ICT (Information and Communication Technology), sensors are, needless to say, an important element, and a near-future society with a network of trillion sensors is expected. Even today, as expressed by the Internet of Things (IoT), many things are connected to the Internet, but in the future this will be extended to humans and robots, and security and efficiency will be dramatically improved. In the materials published on the Ministry of Internal Affairs and Communications (MIC) website, we can see that various working groups are discussing the social infrastructure of the near future.

One of the issues in trillion sensors is the problem of power supply for sensors. It is too inefficient and impractical to replace batteries for a huge number of sensors. As a solution to this problem, the following document published on the website of the Ministry of Internal Affairs and Communications (MIC) discusses a wireless power transmission system for spatial transmission. The higher the frequency, the longer the transmission distance in a wireless power transfer (WPT) system, but the UHF band (920 MHz band), which is widely used for managing objects in the IoT, is assumed first. Although it depends on the output power of the transmitter and receiver, a 1W system can achieve a transmission distance of around 10m. In line with this, the system related to the Radio Law is being developed ("Power supply by radio wave can be used," Asahi Shimbun morning edition, March 8, 2022).

Such sensor networks are expected to expand from the management of objects to human security management. The problem here is that "existing UHF-band RFID tags have almost no communication sensitivity when attached to the human body. This is due to the fact that the human body is a highly dielectric material made of a large amount of water.

We are conducting research and development of wearable UHF-band RFID tags that do not cause communication failures even when attached to a high-k dielectric body such as the human body, for sensing in the near future ICT society (JP2022-074173, JP2022-074174). To solve this problem, the antenna part of the RFID tag had to be specially designed for high-k dielectric materials. On-demand laser processing technology is a very efficient research method for designing and prototyping antenna structures.

Source (Ministry of Internal Affairs and Communications website public documents)

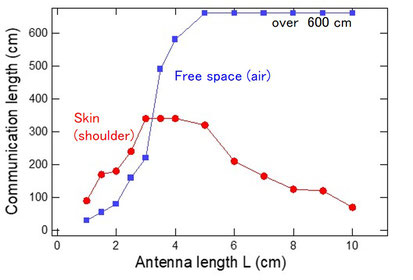

Fig. 2 shows the data comparing the distance at which the RFID tag can communicate with the RFID tag reader/writer in free space (in air) with our developed wearable RFID tag attached to the skin (shoulder) with medical tape (Fig. 1). In this data we can see the effect of antenna length. The communication distance on the human body and in air for our developed RFID tag shape is reversed at around 3 cm, indicating that a structure with a shorter antenna length is preferable for use on the human body. The communication distance also depends significantly on the antenna geometry.

Movie 1 shows the current distribution and vector variation in an antenna of a certain structure calculated by electromagnetic field analysis. In the movie, the rectangular aperture in the center is the impedance matching part, and the parts extending to the left and right of the rectangular aperture are the antenna parts. The central rectangular aperture has a complex impedance, and the capacitive component dominates in contact with a dielectric.

For this reason, in the case of conventional UHF-band RFID tags, when they come into contact with high dielectric materials such as the human body, impedance matching is not achieved, resulting in communication failure. The optimization of the RFID tag structure is difficult to predict by electromagnetic field analysis alone, and requires the optimization of the actual design through prototyping and actual measurement. On-demand laser processing is a suitable method for research and development that requires repeated prototyping.

Fig.1 Wearable UHF-band RFID tag worn on the skin (shoulder)..

Fig.2 Relation between antenna length and communication distance of UHF-band RFID tags in free space and on skin (shoulder).

【Movie1】Variation of Current Distribution and Vector by Electromagnetic Field Analysis of UHF Antenna..

The production of UHF-band RFID tags usually requires large-scale mass-production equipment and a great deal of expense, making it difficult to produce custom products in small lots. We can custom-manufacture and prototype UHF-band RFID tags with various unique characteristics at low cost and in small lots by laser processing (JP2022-109329).