UHF-band RFID tag photo-sensor

Recently, application of RFID technology to the medical and nursing care fields has been studied, and diaper sensors as urination detection sensors have been developed, where changes in the properties of RFID tags due to wetting. Wearable passive RFID tag sensors that do not require batteries or external power sources are expected to become popular in the medical and nursing care fields as devices with a low wearing load. If passive RFID tag sensors can be used not only to detect urination but also to test for contaminants in urine and bodily waste, they will help reduce the burden on medical and nursing care facilities. For example, if we consider detecting changes in components such as blood in urine or latent blood in urine from changes in transmittance, a passive LED tag as light sources and a passive RFID tag photo-sensor as light-receiving elements are required. Since passive LED tags have already been realized, the development of a passive RFID tag photo-sensor is a challenge.

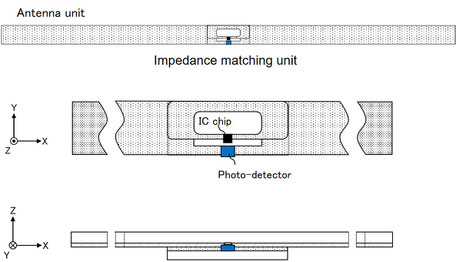

We are conducting research and development of a passive UHF-band RFID tag photo-sensor with a function to quantitatively measure the irradiance of incident light (JP2022-132488). An example is shown in Fig. 1. In addition to the usual impedance matching unit and the antenna part, the impedance matching unit has a second aperture in which a photodetector is connected. The impedance around the second aperture changes depending on the photodetector (phototransistor, photoresistor, etc.) electrically connected to it, and this change can be detected as the sensor code S from the Magnus®-S3 IC to obtain the relationship between the irradiance and the sensor code S. (Fig. 2). The reader RSSI also changes depending on the irradiance, but the RSSI value has a pronounced dependence on the positional relationship between the RFID tag and the reader, making it difficult to use it to detect quantitative changes. In contrast, the sensor code S from Magnus®-S3 is determined by the environment surrounding the IC and can be applied for quantitative measurements.

Fig.1 UHF-band RFID tag photo-sensor.

Fig.2 Relationship between sensor code S and reader RSSI and irradiance observed using a UHF-band RFID tag photo-sensor.

UHF-band RFID tag sensor for Plants

In plant cultivation in a closed-space type plant factory, it is possible to control the temperature, humidity, and other conditions in the plant cultivation house almost uniformly. In contrast, in the case of an open-space type plant factory, the temperature, humidity, and other conditions are not uniform, and information such as environmental temperature and environmental humidity measured in the open space may not reflect the condition of the plants themselves. In order to detect the condition of plants exposed to the natural environment in open spaces, not only in plant factories, it is necessary to measure parameters related to the temperature and dry/humid conditions of the plants themselves.

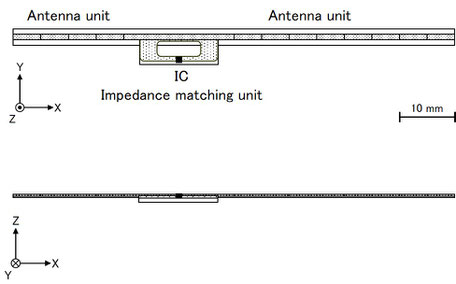

We are conducting research and development of UHF-based RFID tag sensors for plants that are specially designed to be attached to plants (JP2022-177901) as shown in Fig. 3. The antenna consists of several small radiating conductor pieces connected through a polyurethane film (5 µm thick), and so the plant body to which the RFID tag sensor is attached can be moved by stretching and shrinking the polyurethane film.

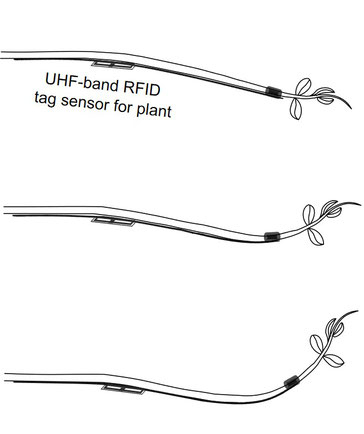

Fig. 4 shows an image of the real-time sensing of phototropism by a RFID tag sensor attached to a plant. the IC chip (Magnus®-S3) can sense the temperature of the plant itself, and the dry and wet conditions of the plant can be determined by changes in the sensor code S. In addition, the antenna of the RFID tag sensor expands and contracts with the phototropism and growth of the plant. The resulting changes in the sensor code S and on-chip RSSI (Received Signal Strength Indicator) make it possible to sense the dynamic behavior of the plant.

Fig.3 UHF-band RFID tag sensor for plants.

Fig.4 Image of real-time sensing of phototropism by RFID tag sensor attached to a plant.

(Ref.) Brett S. Stoddard, Hacking RFID Tags to Produce Economical Soil Moisture Sensors,

https://ir.library.oregonstate.edu/concern/honors_college_theses/4m90f2174

The production of UHF-band RFID tags usually requires large-scale mass-production equipment and a great deal of expense, making it difficult to produce custom products in small lots. We can custom-manufacture and prototype UHF-band RFID tags with various unique characteristics at low cost and in small lots by laser processing (JP2022-109329).